- Products

- Your Business

- Newsroom

- Tools & Resources

- About us

- CSR

- People & Careers

- Search

- Contact us

- Compare

- Sign in

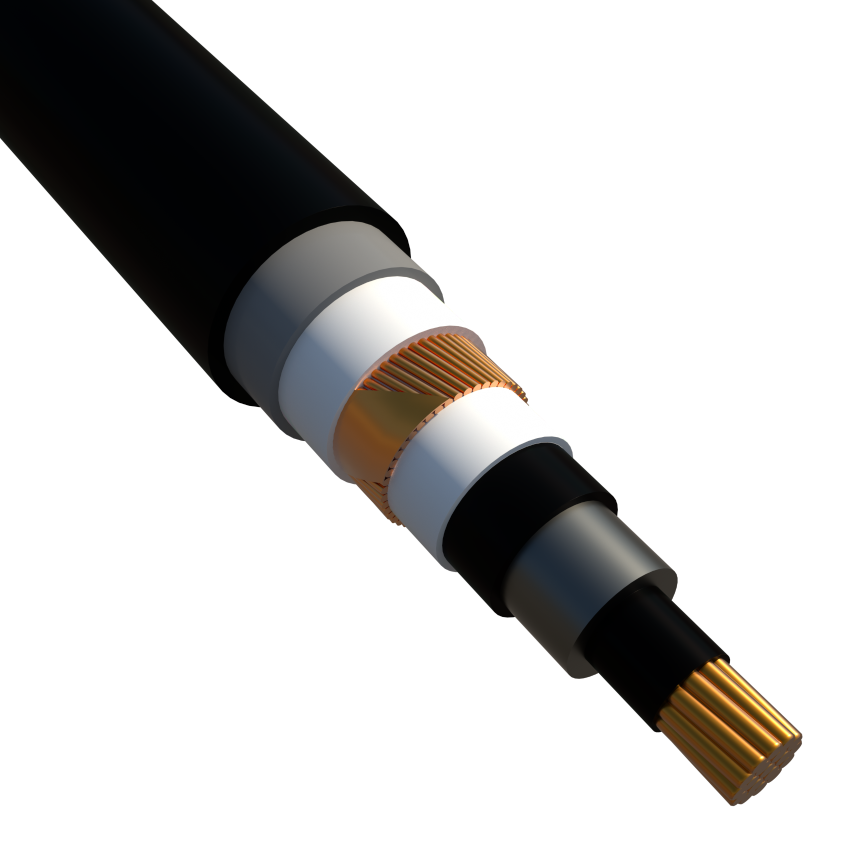

XnRUHKXS armored 3*120/50 12/20kV

XnRUHKXS armored 3*120/50 12/20kV

XLPE Armored cable with copper conductor

Read more- Nexans ref. : M5N4DRP000201

- Country ref. : M5N4DRP 3*120/50(FL)//POL-2R

Description

Description

Standards

-

ProductIEC 60228; IEC 60502-2

-

TestIEC 60332-1-2

CU/SC/XLPE/SC/SC SWEL/CU WIRES/SWEL/ALLUPE/PE/ARMOUR/PE

APPLICATION

Power use outdoor application, even wet.

Suitable for fixed installations at open air, in tube or canals and underground.

Max. Operation temperature: 90°

Max. Short circuit temperature : 250° (Max 5 s)

CONSTRUCTION

1. Conductor:

Compacted Round conductor class 2

2. Insulation:

Extruded inner semi conductive layer, XLPE insulation and extruded outer semi conductive layer

3. Water proof tape:

Semi-conductive swelling tape

4. Metallic screen layer:

Copper wires with open helix copper tape

5. Water proof tape:

Swelling tape

6. Radial water tightness:

Longitudinal PE coated Aluminum Tape

7. Separation sheath:

PE

8. Armour:

Galvanized steel wires armoring

9. Outer sheath:

PE, RED

10. Marking:

By Inkjet printing on one line over the outer jacket

9. Packing:

Drums can be wooden or steel

TEST AT WORKS FOR XnRUHKXS armored

Routine Tests

-Max. DC conductors resistance at 20°C acc. to IEC 60228 & IEC 60502-2 parag. 16.1 & 16.2

-High voltage test acc. to IEC 60502-2 parag. 16.1 & 16.4

-Max. partial discharge test at 1.73 Uo acc. to IEC 60502-2 parag. 16.1 & 16.3

Liban Cables will carry out these tests on all the lengths and tests certificates will be provided

Sample tests

- Check of the build - up and color coding of the cable

- Check of dimensions

Insulation : according to IEC 60502-2 Parag. 17.5.2

Metallic screen : according to IEC 60502-2 Parag. 17.7

Separation sheath: according to IEC 60502-2 Parag.17.5.3

Armouring: according to IEC 60502-2 Parag.17.7

Oversheath : according to IEC 60502-2 Parag. 17.5.3

- Hot Set Test for XLPE insulation according to IEC 60502-2 parag. 17.10

These tests will be carried out on one length of each size during each inspection .

Tests certificates will be provided by Liban Cables

Type tests

Mechanical characteristics on insulation and sheaths material (tensile strength and elongation at break) in accordance with IEC 60502-2.

These tests will be carried out on one length of the order.

Tests certificates will be provided by Liban Cables

Characteristics

Characteristics

Construction characteristics

Construction characteristics

Dimensional characteristics

Dimensional characteristics

Electrical characteristics

Electrical characteristics

Mechanical characteristics

Mechanical characteristics

Usage characteristics

Usage characteristics

Resources

Resources

Declaration of Performance

- Declaration of Performance n� : 1000906-LBNI

- Certification Date : 5/20/20

- AVCP (Assessment and Verification of Constancy of Performance) : System 4

- Declared performance : Fca

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania