- Products

- Your Business

- Newsroom

- Tools & Resources

- About us

- CSR

- People & Careers

- Search

- Contact us

- Compare

- Sign in

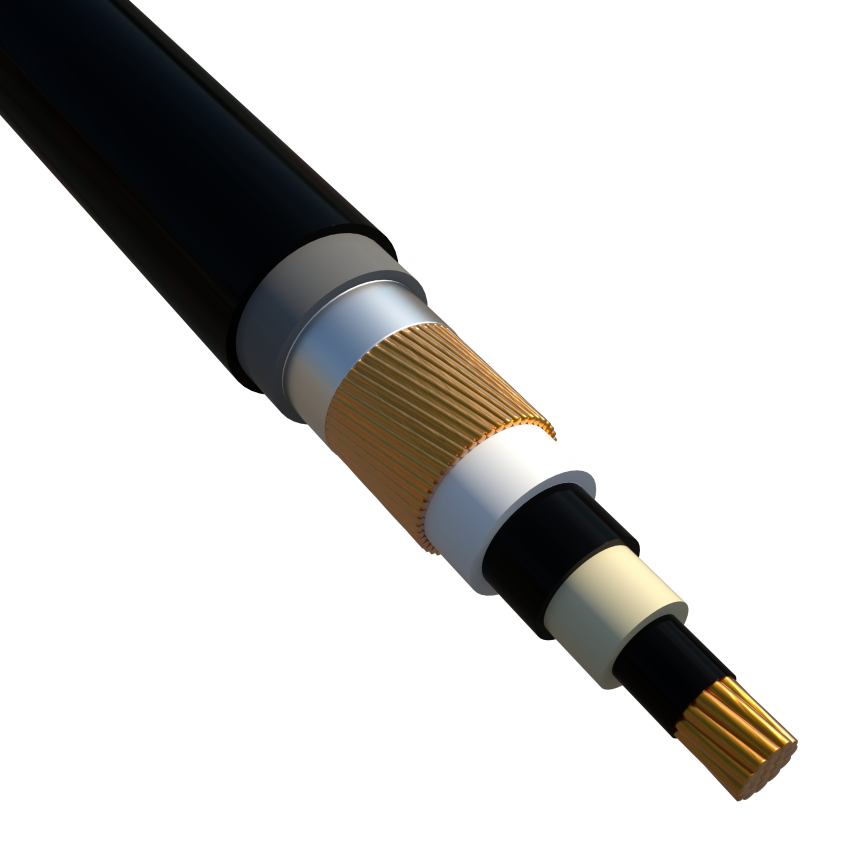

N2XS(FL)2Y 1*240/50 132kV

N2XS(FL)2Y 1*240/50 132kV

76/132 (145)kV Single core Copper XLPE Cable, Cu-Screen, Al-laminated PE sheath

Read more- Nexans ref. : H10N4DP011245

- Country ref. : H10N4DP 1*240/50(FL)//ROM

Description

Description

Standards

-

InternationalIEC 60840

CU/S.C/XLPE/S.C/S.C Swell. tape/Cu wires+OPEN HELIX COPPER TAPE/Swell. tape/Alucopo/PE

APPLICATION

Application in ground, outdoors, in tubes, indoors and in cable ducts.

All high voltage cables are manufactured on the basis of specifications and can be adapted to the requirements of the customer. Therefore, all technical information are purely for information purposes and the electrical characteristics are calculated for values which are specified in the data sheets. For your specific requirements and laying arrangements please don't hesitate to contact us.

DESCRIPTION

Stranded copper conductor class 2 according to IEC 60228, semi conducting conductor screen, insulation of cross-linked polyethylene (XLPE), semi conducting insulation screen, semi conducting swellable tape bedding, copper screen, swellable tape bedding, aluminium tape bonded to PE sheath.

TEST AT WORKS HV CABLES / PRÓBY FABRYCZNE

Routine Tests / Badania rutynowe:

- Max. partial discharge test at 1.5 Uo acc. to IEC 60840 parag.9.2 / Badanie maksymalnych wyładowań niezupełnych przy 1,5 Uo zgodnie z IEC 60840 pkt 9.2

- High voltage test acc. to IEC 60840 parag. 9.3 / Próba wysokim napięciem zgodnie z IEC 60840 pkt 9.3

Liban Cables will carry out these tests on all the lengths and tests certificates will be provided / Firma Liban Cables przeprowadzi te badania dla wszystkich odcinków kabli i dostarczy świadectwa z badań

Sample tests / Badania próbek:

- Conductor examination acc. to IEC 60840 parag. 10.4 / Badanie dyrygenta IEC 60840 pkt 10.4

- Max. DC resistance of conductor acc. to IEC 60840 parag. 10.5 / Maks. rezystancja DC żył i IEC 60840 pkt 10.5

- Check of dimensions / Sprawdzenie wymiarów

Insulation / Izolacja : according to IEC 60840 / zgodnie z IEC 60840 Parag. 10.6.2 / pkt 10.6.2

Metallic screen / Ekran metaliczny : according to IEC 60840 / zgodnie z IEC 60840 Parag. 10.7 / pkt 10.7

Oversheath / Powłoka zewnętrzna : according to IEC 60840 / zgodnie z IEC 60840 Parag. 10.6.3 / pkt 10.6.3

- Hot set test for insulation XLPE acc. to IEC 60840 parag. 10.9 /-Badanie stopnia usieciowania izolacji z XLPE zgodnie z IEC 60840 pkt 10.9

- Measurement of capacitance acc. to IEC 60840 parag. 10.10 / Pomiar pojemności zgodnie z IEC 60840 pkt 10.10

These tests will be carried out on one length of each size during each inspection / Badania te – podczas każdej kontroli – zostaną przeprowadzone na jednym odcinku dla każdego rozmiaru kabla.

Tests certificates will be provided by Liban Cables / Świadectwa z badań dostarczy firma Liban Cables.

DRAWING LAYERS HV 132KV

Characteristics

Characteristics

Construction characteristics

Construction characteristics

Dimensional characteristics

Dimensional characteristics

Electrical characteristics

Electrical characteristics

Mechanical characteristics

Mechanical characteristics

Usage characteristics

Usage characteristics

Resources

Resources

Declaration of Performance

- Declaration of Performance n� : 1000855-LBNI

- Certification Date : 5/20/20

- AVCP (Assessment and Verification of Constancy of Performance) : System 4

- Declared performance : Fca

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania