- Products

- Your Business

- Newsroom

- Tools & Resources

- About us

- CSR

- People & Careers

- Search

- Contact us

- Compare

- Sign in

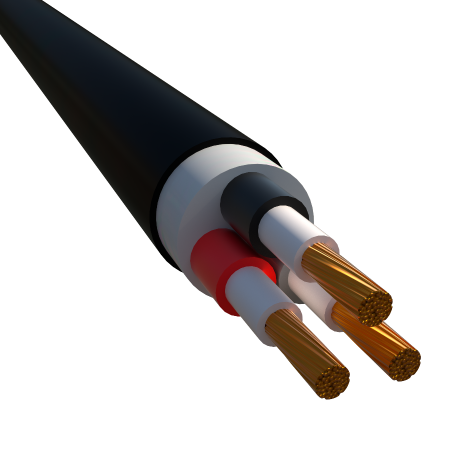

Energy LV Fire Resistant

- 9 families

Energy LV Fire Resistant

Energy LV Fire Resistant

Energy LV Fire Resistant

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania